PUBLIC TRAININGS

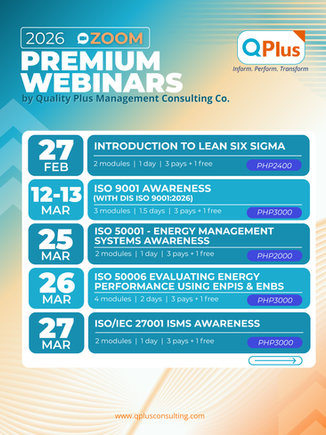

Quality Plus Management Consulting Co. offers a range of webinars—both paid and free—along with in-person seminars and training sessions at our business locations.

Our public seminars and training sessions are open to participants from various organizations and industries. These sessions are designed to cultivate a collaborative learning environment and provide valuable knowledge and skills to professionals from different companies. We warmly welcome you to join and benefit from these opportunities.

Explore Schedules by Location. Click the tabs below to view QPlus seminar schedules for each business location.

Check the calendar below for full details.

Click any date to explore your desired topic.

*Please note that schedules and details are subject to change without prior notice. Follow our online platforms for the latest updates!*

.png)

.png)

.png)